The most expensive monitoring mistake I ever saw cost a customer in Elk Grove $3,800 to fix. They thought their pool was "fine" running unattended through winter because Sacramento has mild weather. But their pump seal developed a slow leak in January that went unnoticed for six weeks. By the time they discovered it, the pump had been running dry intermittently, destroying the impeller and motor while their water level dropped below the skimmer. What should have been routine winter monitoring became emergency equipment replacement during peak season pricing.

I learned early in my career that Sacramento’s "mild" winter creates a false sense of security that leads to expensive mistakes. Yes, we don’t need to drain pipes or shut down completely, but equipment still needs professional attention during dormancy because problems that develop slowly become expensive when they’re not caught early.

After 35+ years of Sacramento pool equipment management, I’ve developed dormancy preparation strategies that keep equipment running efficiently at reduced levels while catching problems before they become emergencies. The key is understanding that dormancy isn’t neglect—it’s optimized operation with strategic monitoring.

Here’s what Sacramento pool owners need to know about equipment dormancy preparation and monitoring.

Understanding Sacramento’s Equipment Advantage

Sacramento pool equipment gets a unique advantage because our mild climate allows continued operation rather than complete shutdown, but this advantage requires professional management to realize its benefits.

The Continuous Operation Benefit

Equipment that keeps running stays healthier than equipment that sits idle for months because seals stay lubricated, moving parts don’t seize, and problems get detected before they cause major damage.

Continuous operation advantages:

- Seal preservation preventing drying and cracking from disuse

- Component lubrication maintaining optimal mechanical condition

- Problem detection ongoing operation revealing developing issues early

- System readiness equipment ready for increased demand when needed

Joe’s Pro Tip: Sacramento equipment that runs at reduced levels through winter typically lasts 2-3 years longer than equipment that gets shut down and restarted annually. Movement is medicine for mechanical systems.

The key is optimized operation that provides equipment protection and system functionality while dramatically reducing energy costs and maintenance demands compared to full summer operation.

Dormancy vs Shutdown Economics

Running equipment at 25% capacity costs far less than shutting down and restarting while providing superior equipment protection and water quality maintenance.

Dormancy operation economics:

- 50-75% energy reduction compared to summer operation levels

- Equipment protection through continued lubrication and movement

- Monitoring capability detecting problems when they’re still affordable

- System readiness immediate response to weather changes or usage needs

Professional optimization determines the minimal operation level that maintains protection while maximizing energy savings and system longevity.

I worked with a customer in Granite Bay who insisted on shutting down completely to "save money." After three years of expensive spring startups and equipment failures, they realized dormancy operation actually cost less while providing superior results.

Strategic Equipment Programming

Optimal dormancy requires professional programming that balances protection with efficiency while accounting for Sacramento’s variable winter weather and usage patterns.

Circulation System Optimization

Professional runtime calculation considers pool volume, circulation requirements, chemical distribution needs, and equipment protection to determine optimal dormancy schedules.

Runtime optimization factors:

- Complete pool turnover ensuring all water circulates within 24-48 hours

- Chemical distribution maintaining sanitizer effectiveness throughout the pool

- Debris suspension preventing accumulation in low-flow areas

- Equipment protection adequate flow for pump cooling and lubrication

Utility rate coordination maximizes savings by scheduling operation during off-peak hours when both PG&E and SMUD offer reduced electricity rates.

Professional programming typically reduces operation 50-75% while maintaining adequate circulation for water quality and equipment protection throughout dormancy.

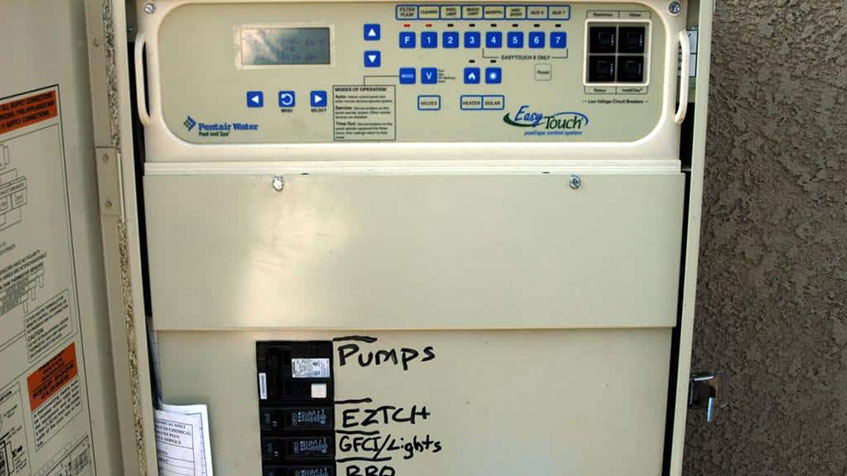

Automation System Calibration

Modern automation systems allow sophisticated programming that coordinates circulation, heating, chemical feed, and cleaning systems for maximum dormancy efficiency.

Automation programming benefits:

- System coordination integrating multiple systems for optimal efficiency

- Weather responsiveness adapting operation for changing conditions

- Professional calibration ensuring systems work together effectively

- Energy optimization minimizing consumption while maintaining performance

Seasonal programming adjustments account for shorter daylight hours, cooler temperatures, and reduced chemical demands through professional calibration.

Chemical Feed System Adaptation

Automated chemical systems require recalibration for dormancy conditions because reduced circulation and cooler temperatures change chemical demand and distribution patterns.

Chemical system adjustments:

- Salt chlorinator output reducing production for cooler weather demands

- Chemical feeder rates adjusting for reduced flow and chemical needs

- Sensor calibration ensuring accurate readings despite changed conditions

- Professional programming optimizing delivery for dormancy requirements

Sacramento’s hard water affects chemical systems differently during dormancy, requiring professional adjustment to prevent scaling while maintaining adequate sanitization.

Equipment Protection Strategies

Sacramento’s occasional weather extremes require flexible protection strategies that maintain normal operation while providing safeguards for unusual conditions.

Cold Weather Protection

Brief temperature drops below freezing occur occasionally in Sacramento, requiring minimal protection measures without extensive winterization procedures.

Cold weather protection basics:

- Circulation maintenance ensuring water movement during cold periods

- Equipment monitoring checking operation during temperature drops

- Minimal line drainage protecting most exposed plumbing if needed

- Professional protocols expert guidance for individual equipment configurations

Emergency procedures ensure pool owners know how to protect equipment during unexpected temperature drops while maintaining system functionality.

Variable Weather Adaptation

Sacramento’s winter weather varies dramatically from 70°F sunny days to 35°F rainy periods, requiring equipment programming that adapts to changing conditions.

Weather adaptation strategies:

- Temperature-responsive programming adjusting operation for weather changes

- Automated adaptation systems that modify operation based on conditions

- Professional monitoring expert oversight during unusual weather periods

- Flexible scheduling capability to increase operation during warm spells

Professional weather protocols provide specific guidance for protecting equipment during unusual conditions while maintaining optimal operation during normal dormancy periods.

Monitoring: The Key to Success

Effective dormancy monitoring prevents small problems from becoming expensive emergencies while ensuring equipment operates optimally throughout winter.

Professional vs DIY Monitoring

Professional monitoring provides systematic attention that catches problems early when they’re still affordable and manageable rather than waiting until they become obvious and expensive.

Professional monitoring advantages:

- Systematic inspection preventing problems before they become emergencies

- Expert assessment professional evaluation of equipment and water conditions

- Problem pattern recognition identifying developing issues from subtle signs

- Immediate intervention addressing problems when solutions are simple

DIY monitoring limitations include missing subtle warning signs, lack of professional equipment for testing, and inability to recognize patterns that indicate developing problems.

The leak detection scenario shows why professional monitoring matters: slow leaks can continue for weeks before becoming obvious to homeowners, while professionals detect them immediately through systematic inspection.

Critical Monitoring Parameters

Equipment performance monitoring focuses on parameters that indicate developing problems requiring attention before they cause equipment failure or water quality issues.

Key monitoring elements:

- Performance indicators listening for unusual sounds and checking operation

- Pressure monitoring tracking filter and circulation system performance

- Water level management ensuring adequate water for equipment protection

- Chemical balance maintaining optimal conditions with reduced operation

Professional monitoring equipment provides accuracy that home testing cannot achieve while enabling detection of problems that aren’t obvious to casual observation.

Early Intervention Benefits

Catching problems early typically reduces repair costs by 60-80% compared to waiting until equipment fails or water quality deteriorates significantly.

Early intervention examples:

- Seal replacement before pump damage occurs

- Filter cleaning before pressure buildup damages circulation systems

- Chemical adjustment before water quality creates equipment or surface problems

- Equipment calibration before performance degradation becomes obvious

One customer shared their experience with professional monitoring: "They caught a small leak in my filter housing that I never would have noticed. The $85 repair saved me from a much bigger problem later." The early detection prevented a $800 equipment replacement.

Common Dormancy Mistakes

Understanding typical mistakes helps pool owners avoid expensive problems while appreciating the value of professional dormancy management.

The "Set and Forget" Trap

Assuming equipment needs no attention during dormancy leads to gradual performance degradation and eventual failures that professional monitoring prevents.

Common neglect problems:

- Performance degradation gradual decline affecting efficiency and reliability

- Unexpected failures equipment problems developing without warning

- Water quality deterioration chemical imbalances creating restoration needs

- Safety concerns equipment malfunctions creating hazardous conditions

Professional attention prevents these scenarios through systematic monitoring that identifies problems when they’re still manageable and affordable.

Inadequate Chemical Management

Skipping water chemistry monitoring during cooler weather allows imbalances that damage equipment and surfaces while creating conditions for contamination.

Chemical neglect consequences:

- Equipment scaling mineral deposits reducing efficiency and causing damage

- Surface staining chemical imbalances creating permanent discoloration

- Algae development contamination requiring expensive treatment

- System damage chemical extremes damaging pumps, filters, and surfaces

Professional chemical monitoring maintains optimal balance while preventing damage through expert understanding of dormancy requirements.

Emergency Response Gaps

Lack of professional emergency support means problems that develop during dormancy become expensive crises instead of manageable maintenance issues.

Emergency response value:

- Rapid intervention quick professional response preventing damage escalation

- Expert diagnosis proper problem identification and solution implementation

- Damage prevention immediate attention protecting equipment and water quality

- Cost control emergency intervention typically less expensive than delayed repair

Professional Service Programs

Pool Time’s dormancy programs provide comprehensive equipment management designed specifically for Sacramento’s climate and conditions.

Professional dormancy management includes: systematic weekly monitoring ensuring consistent attention to changing conditions, expert equipment assessment evaluating system performance and identifying developing issues, comprehensive chemical management maintaining optimal water quality throughout dormancy periods, and emergency response availability providing immediate professional intervention when problems develop requiring rapid solutions.

Custom program design meets individual pool requirements and budget considerations while ensuring comprehensive equipment protection and optimal dormancy management.

Technology Integration

Advanced monitoring technology supplements professional expertise while providing continuous assessment of critical parameters and automated alerts when conditions require attention.

Technology benefits:

- Continuous monitoring 24/7 assessment of equipment performance and water conditions

- Early detection automated alerts when parameters exceed optimal ranges

- Professional integration technology supporting expert decision-making

- Remote management professional adjustment based on real-time conditions

Professional technology integration ensures automated systems enhance rather than replace expert human assessment for optimal results.

Making Dormancy Work for You

Successful dormancy management requires understanding Sacramento’s unique conditions and implementing professional strategies that optimize equipment protection while minimizing costs.

Dormancy success factors:

- Professional programming expert optimization for local conditions

- Systematic monitoring consistent attention preventing problems

- Early intervention addressing issues when solutions are simple

- Emergency support professional response when problems develop

Professional expertise ensures dormancy preparation addresses all equipment needs while optimizing operation for Sacramento’s specific conditions and requirements.

With over 3 decades of experience managing Sacramento pool equipment through dormancy periods, I’ve learned that the pools with the most reliable equipment and lowest total costs are those that receive professional dormancy management. It’s not about doing less—it’s about doing the right things at the right times with expert guidance.

If you want to understand how professional dormancy preparation can protect your equipment while reducing costs through optimized operation, give me a call at 916-638-7665. I’m always happy to chat about equipment programming and monitoring strategies that work best for your specific system and our unique conditions—no pressure, just straight answers from someone who’s optimized every type of pool equipment for Sacramento’s dormancy requirements.

Visit our weekly pool service to learn more about professional dormancy monitoring that keeps equipment running optimally, or explore our equipment and repair services for expert equipment programming and optimization, or check out our pool spa services for comprehensive dormancy preparation designed for Sacramento’s unique conditions.

Pool Time Pool & Spa has been Sacramento’s trusted equipment dormancy expert for over 35 years. As a locally owned business that’s fully licensed, bonded, and insured, we provide optimal system management and monitoring that ensures reliable performance throughout winter while protecting substantial equipment investments through professional expertise.